一.Function Introduction

FE-FRS1-C001 is used for Feetech PWM programmable servo, with the following functions:

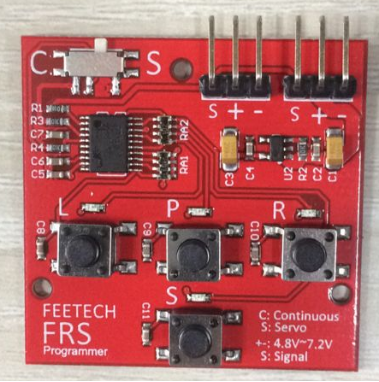

1.Double mode switching (servo mode and motor mode), support offline operation. After setting, disconnect FE-FRS1-C001 and send PWM signal to realize current mode operation.

Servo mode: According to the corresponding proportional relationship between the pulse width and the angle, the control of the angle is realized, and the rotation direction is calibrated with reference to the factory specification.

Motor mode: According to the relationship of the rotation direction corresponding to the pulse, it realizes continuous clockwise and counterclockwise rotation. The pulse is 1500us to stop, 500us corresponds to counterclockwise rotation, and 2500us corresponds to clockwise rotation. The closer it is to 1500us, the slower the speed will be; the motion process is not closed-loop controlled, that is, within a certain range, the speed and load increase, and the intelligent maintenance does not decelerate.

2. Angular rotation test of servo mode and motor mode, starting point, middle point, end point three-point test and reciprocating rotation test in servo mode. Clockwise rotation of motor mode, stop, counterclockwise rotation;

3. The angle limit in the servo mode, the range of the rotation angle is electronically limited, and the offline operation is supported.

二、Instructions

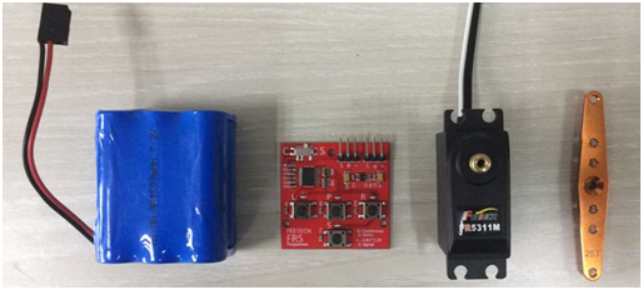

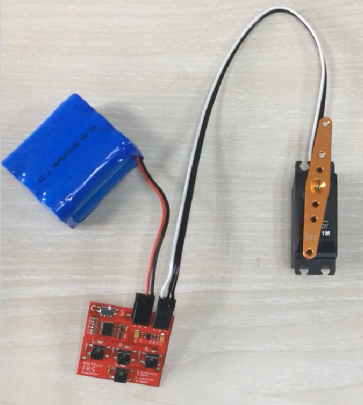

1、Advance preparatio

1)、DC power supply DC4.8-7.2V

2)、FEETECH FRS programmer (red PCBA)

3)、FR5311M Servo

4)、25T Servo horn

2、Line order definition:

- : DC negative

+: DC positive

S: Servo Signal

3、Set Servo Mode

All LED at off status

a: Selected switch to “S”side

b: Long press the “P”key (> 5 second)

c: all LEDs will flash when program completed

d: Servo have set to work at Servo Mode

4、Test Servo

a: Press“S”key (one time)

b: Into auto sweep test mode, and“S” LED will quick flash

c: Press“S”key (tow time)

d: Into 3 point test mode, and“S” LED will slow flash

e: Press“L”key Servo will go to the LEFT side position

f: Press“P”key Servo will go to the MIDDLE position

g: Press“R”key Servo will go to the RIGHT side position

h: Press“S”key (three time)

i: Back to program mode, and all LED will off

5、Set Continuous Rotation Mode

All LED at off status

a: Selected switch to “C”side

b: Long press the “P”key (> 5 second)

c: all LEDs will flash when program completed

d: Servo have set to work at Continuous Rotation Mode

e: Test servo can stop at MIDDLE position, CCW at LEFT position and CW at RIGHT position

6.set angular stroke limi

All LED at off status

a: Selected switch to “S”side

b:Turn the Servo horn to the starting point

c:Short press the "L" key, the indicator light flashes 3 times

d:Turn the Servo horn to the end point

e:Short press the "R" key, the indicator light flashes 3 times

f:Short press the "P" key, the indicator light flashes 3 times,Setup is complete

g:Press "S" key to enter circular rotation

h:Press the "S" key again to enter the test mode, at this time, "P" is long on and "S" is flashing

i:Press the "L" key the servo will rotate to the starting point

j:Press the "R" key the servo will rotate to the end point

k:Press the "S" key,All LED at off status

l:Long press the “P”key (> 5 second),Restore factory settings,Release maximum angular travel

7、FE-FRS1-C001Supported Models:

FT5116M

FT5118M

FB5116M

FB5118M

FR5311M

FR5317M

FT5320M

FT5325M

FT5330M

FT5825M

FT5830M

FT5835M

8、Reference video

Video link,Click me to jump